Hydrogen production

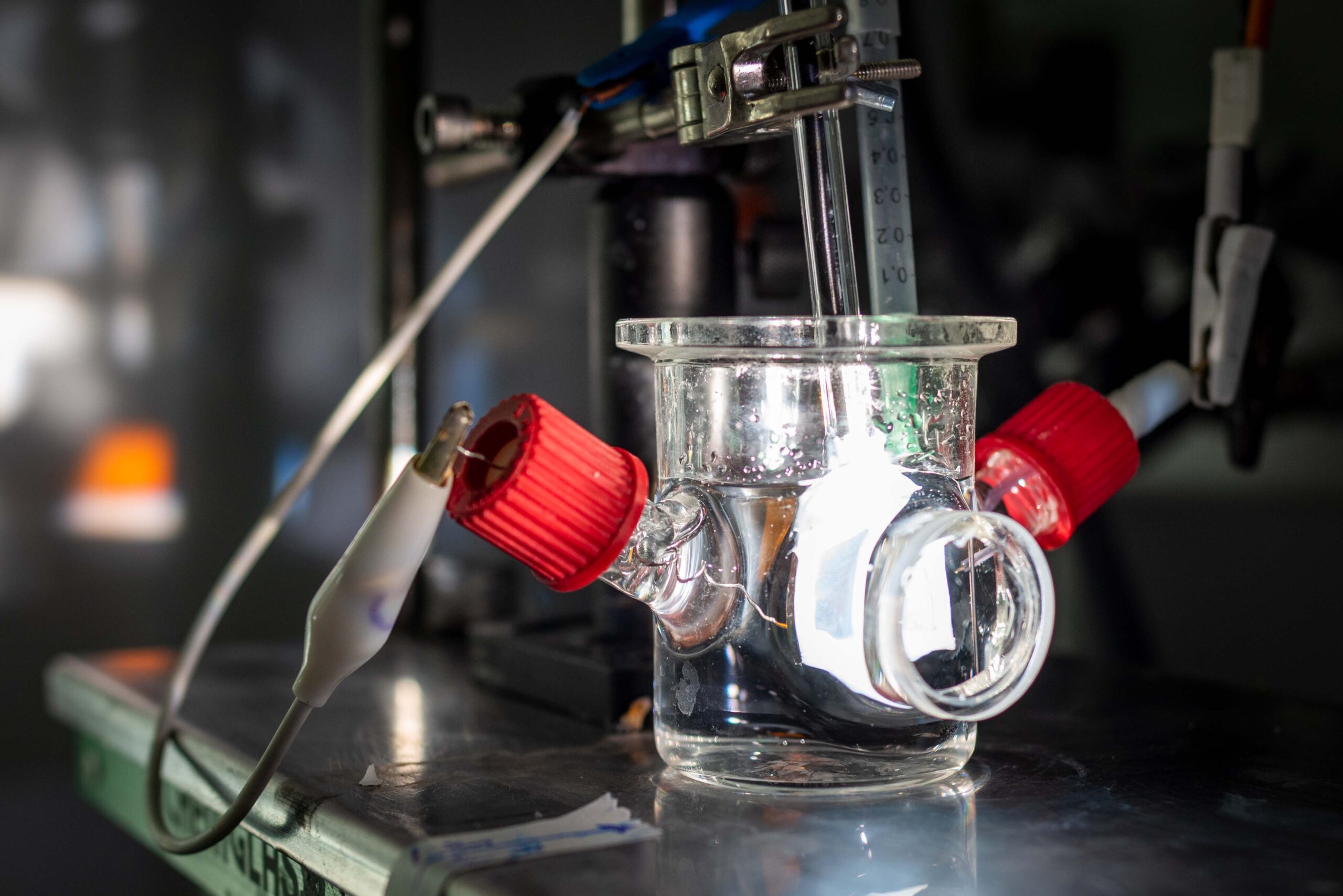

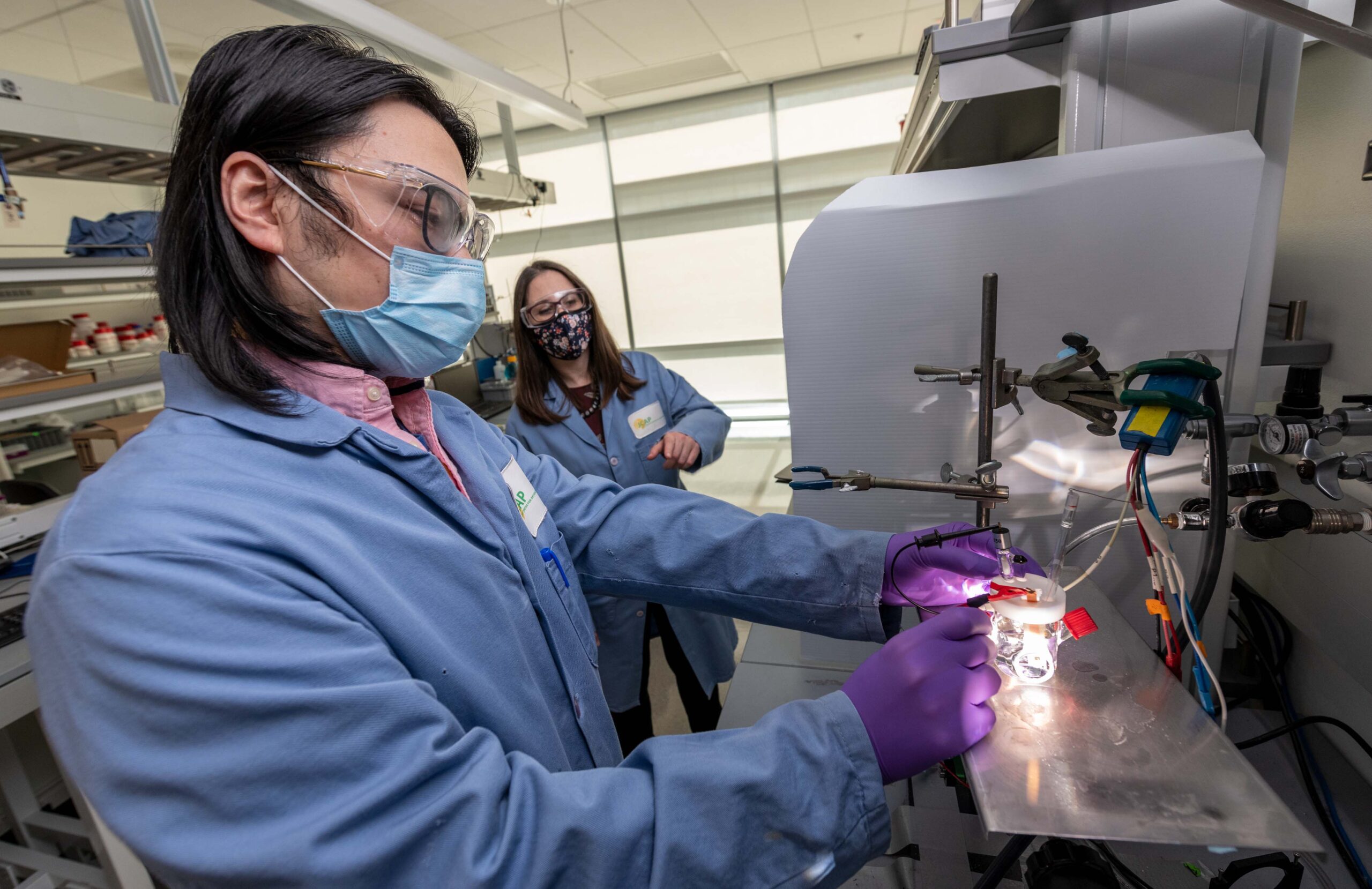

Reduce the cost and increase the durability of electrolyzers and advanced pathways to meet the U.S. Department of Energy’s Hydrogen Shot targets.

Hydrogen delivery and storage

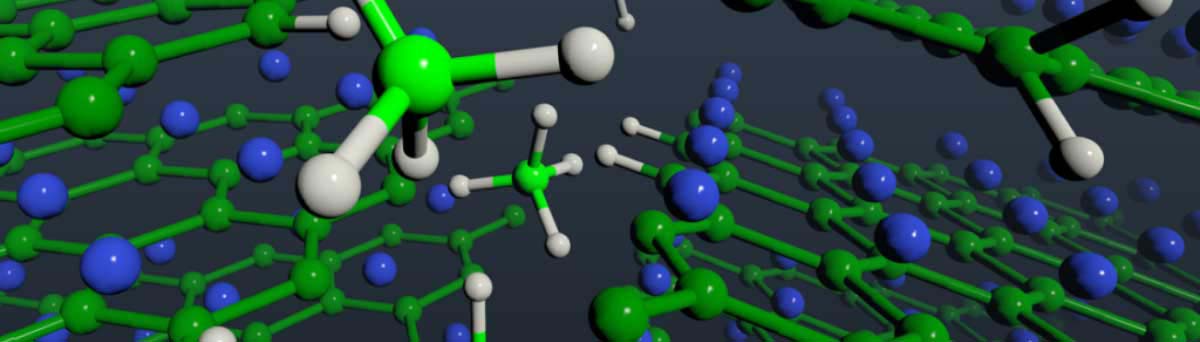

Synthesize, characterize, and mechanistically understand novel hydrogen storage hydrides, sorbents, chemical carriers, and porous media.

Hydrogen utilization

Improve hydrogen technology efficiency and durability through advanced integration with a focus on fuel cells for transportation and heavy-duty applications.

Advanced materials

Advanced characterization and simulation to increase discovery, performance, and durability of materials from atoms to assemblies for hydrogen technologies.

Hydrogen analysis

Techno-economic analysis to identify applications and understand targets for hydrogen technologies to inform required advances and validate progress toward cost targets, scale-up, and manufacturing.

HyMARC Energy Materials Network is focused on advanced materials for hydrogen storage including sorbents, hydrides, and chemical carriers.

BioH2 focuses on the conversion of lignocellulosic biomass to H2 by biological high-temperature fermentation.

M2FCT focuses on research and development to enable a fully competitive, heavy-duty fuel cell truck that can meet the required durability, cost, and performance metrics.

H2NEW focuses on reducing cost and increasing performance and durability of low- and high-temperature electrolyzers for producing hydrogen by splitting water.

HydroGEN Energy Materials Network focuses on advanced water-splitting materials and pathways such as alkaline and acid-based electrolysis, as well as direct-solar pathways (photoelectrochemical, solar thermochemical).

CHyTAC focuses on identifying, disseminating, and driving application of consensus-driven solutions for rapidly realizable interconnectivity of clean hydrogen deployments.

A crosscutting technology that comprises an electrolyzer and fuel cells in one device, which serves as an energy conversion device combined with scalable storage with high energy densities.

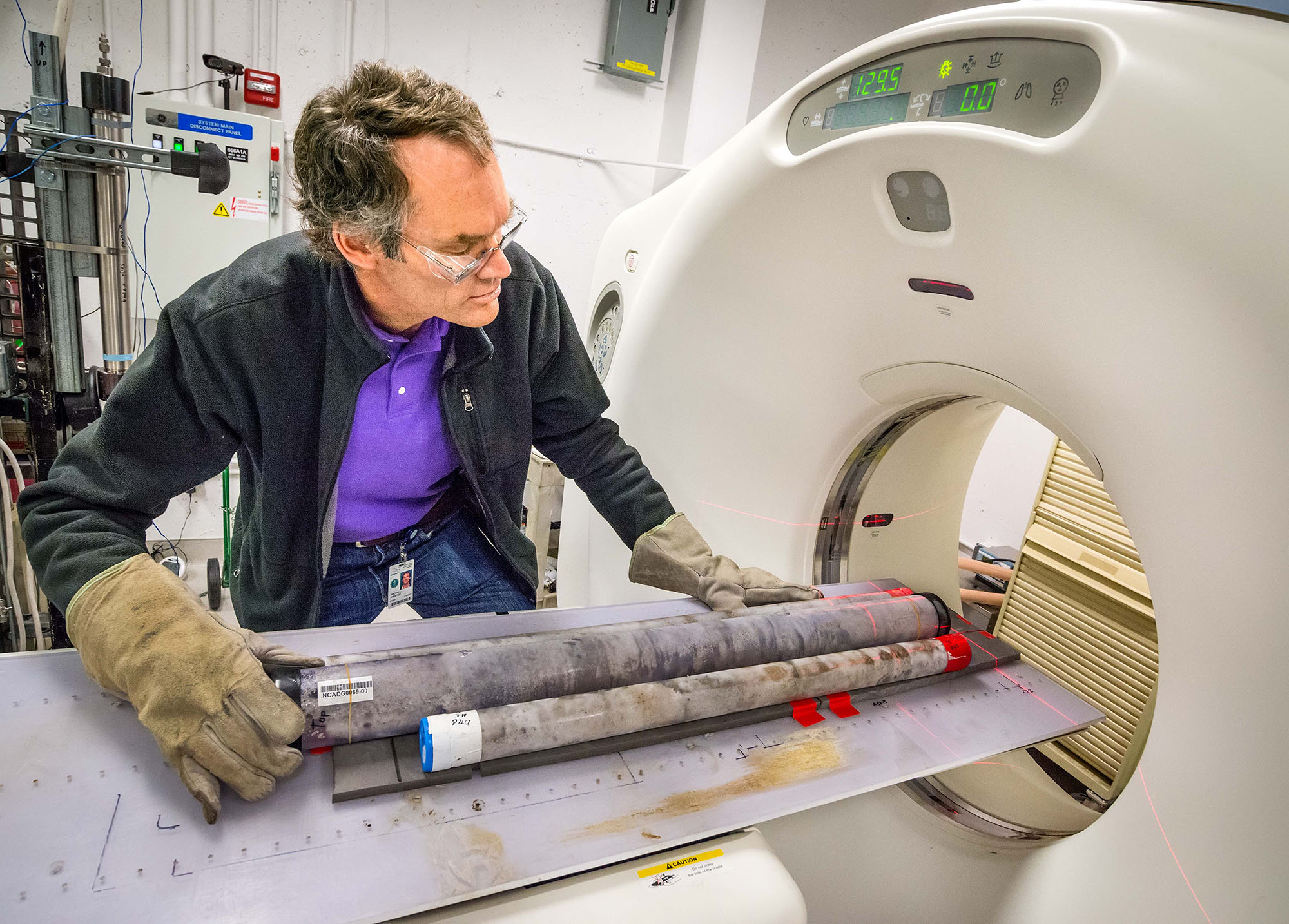

Berkeley Lab is establishing a consortium and vision for a field research study to assess the safety and efficiency of large-scale geologic storage in California.

Berkeley Lab conducts unbiased analysis to evaluate the cost implications and environmental impacts of a wide range of energy technologies and strategies to support decision-making by groups.

A multidisciplinary team focused on a diverse portfolio of advanced energy conversion technologies with the goal of providing the tools necessary to create and sustain a clean energy system.

A senior scientist in the Energy Technologies Area, Rangachary Mukundan's research interests include fuel cells, electrolyzers, flow batteries, and sensors. He is serving as deputy director in DOE’s Million Mile Fuel Cell Truck (M2FCT) and Hydrogen from Next generation Electrolyzers of Water (H2NEW) consortia.

Hanna Breunig is a Research Scientist and Deputy-Head of the Sustainable Energy and Environmental Systems Department in the Energy Analysis and Environmental Impacts Division. She specializes in techno-economic analysis, process modeling, market analysis, and environmental and human health impact assessment (life-cycle assessment) of emerging energy and negative emissions technologies.

Ahmet Kusoglu is a Scientist in the Energy Conversion Group at the Energy Technologies Area, working on polymeric and functional materials for hydrogen and clean energy applications. His research focuses on the characterization of ion-conductive polymers and solid-electrolyte interfaces for energy conversion and storage devices and understanding related electrochemical-mechanical phenomena.

We have more than 100 researchers publishing on the many aspects of hydrogen. Read our publications on hydrogen.

Berkeley Lab scientists are leading local and national projects aimed at optimizing all stages of the hydrogen energy lifecycle, from engineering technologies for cost-effective and environmentally friendly production of hydrogen gas all the way to developing efficient hydrogen fuel cells.

Here’s a round-up of our current focus areas encompassing hydrogen production, storage, usage, and analysis, to enable a carbon-free future.

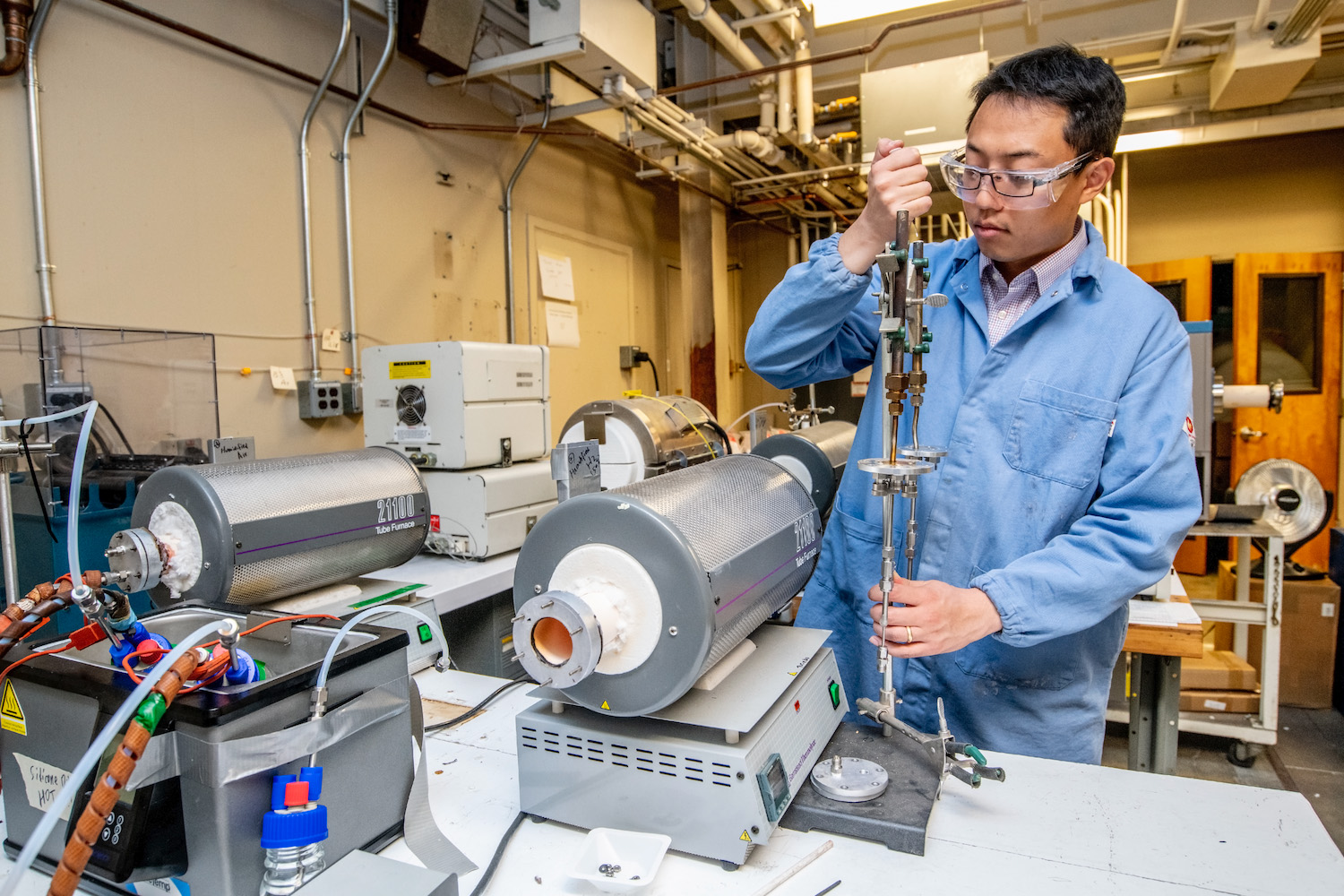

Solid oxide electrolysis cells that operate at high temperature provide high performance and efficiency, and can make use of waste heat or steam from industrial or geothermal sources. Lawrence Berkeley National Laboratory (Berkeley Lab) researchers are working to reduce the cost and increase the durability of electrolyzers and advanced pathways.

In this episode, we discuss the past, present, and future of hydrogen energy, including the dirty side of hydrogen production and the current push for zero-emissions hydrogen to power our daily lives and decarbonize big-ticket industries like steel manufacturing.